The majority of occupied buildings in the UK are served by hot water storage and distribution systems. Where a building is being used by people other than the owner of the building (third parties), the owner (or manager) of the building has a duty of care to ensure that the others can use the building and its facilities safely.

The role of the building services professional is important in ensuring that hot water and storage systems are designed, installed, serviced and maintained so that risks from scalding or bacterial infection are reduced to an absolute minimum. Despite this, every year in the UK a significant number of building occupants are injured or die because of these risks. All these injuries are wholly preventable by the installation and use of appropriate safety products.

The risk

There are two areas of risk with hot water systems:

- Scalding from hot water

- Legionella infection typically from stored hot water

Both these areas of risk arise from the storage and delivery of hot water for use by building occupants. Effective measures can be used to minimise the risks for both scalding and Legionella. However, in many cases the control measures needed to reduce either one of the risks increases the potential risk from the other.

Hot water temperatures that do not cause scalding are ideal for the Legionella bacteria to grow in a water system, but hot water temperatures that kill the Legionella bacteria can cause scalding.

Scalding

Scalding can occur in many situations in all types of building both public and private. In whichever situation, the temperatures at which scalding can occur are constant, but the degree of potential scalding does depend on the temperature and volume of delivered hot water and the contact time.

Evidence on scalding indicates a risk increasing rapidly from temperatures of 45ºC and above. For example, partial thickness burns will occur within 30 seconds at 55ºC, reducing to less than 5 seconds at 60ºC and above. These examples are taken from figures represented in the NHS Estates Health Guidance note, ‘SAFE hot water and surface temperatures’ but are only guideline figures. Skin sensitivities vary greatly throughout the population, as do the risks from high temperatures for the population with specific medical conditions.

Recommended safe hot water temperatures

The NHS Estates Health Guidance Note refers to maximum hot water and surface temperatures for safe use. These are recommended for all healthcare premises and those premises registered under the Registered Homes Act 1984 but are applicable for other types of occupied building.

- 44ºC for an unassisted bath fill

- 46ºC for an assisted bath fill (**)

- 41ºC for shower applications

- 41ºC for washbasin applications

- 38ºC for bidet applications

** This high fill temperature should only be considered in exceptional circumstances where there are difficulties in achieving an adequate bathing temperature. The building manager should also have in place specific policies that prevent the possibility of persons judged to be at risk gaining access to the bath unaccompanied.

Legionella

Legionella bacteria are naturally occurring organisms present in many water systems, and if exposed to human beings can cause the development of Legionnaires’ disease. The evidence for the occurrence of Legionella in water systems varies between different reports.

The most representative information is summarised in an HSE ACOP L8 2013 (4th addition) document, which states:

- Legionella bacteria will die at temperatures above 60ºC.

- Legionella bacteria proliferate between 20ºC and 45ºC.

- Legionella bacteria will not multiply at temperatures below 20ºC but will remain a potential threat in the system.

Recommended measures to control Legionella

- The water distribution system should always be maintained in a hygienic condition.

- Ensure that water supplies are distributed to the point of mixing, either below 20ºC for cold supplies or above 55ºC for hot supplies.

- Hot water should be stored at or above 60ºC.

The control of discharge temperatures

The control of delivered hot water temperatures coupled with the control of stored and distribution hot water temperature is the key to safe hot water provision. The objectives of any control system are to store water at above 60ºC, distribute water at 55-60ºC, yet deliver water at discharge temperatures between 35-46ºC.

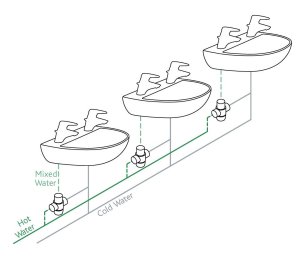

The most effective means to achieve both objectives is to store and distribute water at high temperatures and use Thermostatic Mixing Valves (TMVs) to reduce discharge temperatures to appropriate levels.

Guidance

The ACOP L8 2013 (4th addition) states the following:

Thermostatic Mixing Valves

TMVs are valves that use a temperature sensitive element and blend hot and cold water to produce water at a temperature that safeguards against the risk of scalding, typically between 38 °C and 46 °C depending on outlet use. The blended water downstream of TMVs may provide an environment in which Legionella can multiply, thus increasing the risks of exposure.

The use and fitting of TMVs should be informed by a comparative assessment of scalding risk versus the risk of infection from Legionella. Where a risk assessment identifies the risk of scalding is insignificant, TMVs are not required. The most serious risk of scalding is where there is whole body immersion, such as with baths and showers, particularly for the very young and elderly, and TMVs should be fitted at these outlets. Where a risk assessment identifies a significant scalding risk is present, e.g. where there are very young, very elderly, infirm or significantly mentally or physically disabled people or those with sensory loss, fitting TMVs at appropriate outlets, such as hand washbasins and sinks, is required.

Where TMVs are fitted, consider the following factors:

-

- where practicable, TMVs should be incorporated directly in the tap fitting, and mixing at the point of outlet is preferable;

- where TMVs are fitted with low flow rate spray taps on hand washbasins, the risk is increased;

- TMV valves should be as close to the POU as possible to minimise the storage of blended water;

- where a single TMV serves multiple tap outlets, the risk can be increased;

- where TMVs are designed to supply both cold and blended water, an

- additional separate cold tap is rarely needed and may become a low use outlet.

Maintenance

TMVs need regular servicing to ensure they remain effective in reducing the risk of scalding, the ACOP L8 2013 (4th addition) recommend the following:

Service: TMV

Action To Take: Risk assess whether the TMV fitting is required, and if not, remove. Where needed, inspect, clean, descale and disinfect any strainers or filters associated with TMVs. To maintain protection against scald risk, TMVs require regular routine maintenance carried out by competent persons in accordance with the manufacturer’s instructions. There is further information in paragraphs 2.152– 2.168.

Frequency: Annually or on a frequency defined by the risk assessment, taking account of any manufacturer’s recommendations.

Conclusion

TMVs should be avoided wherever possible, however where the risk of scalding needs to be controlled, TMVs will need to be fitted, ideally individual TMVs per outlet, fitted as close as possible to the outlet so to reduce the amount of blended water below 50°C in the system.

It is critical the TMV is installed and commissioned correctly and is regularly maintained and monitored, so the TMV acts as an effective device for reducing the risk of scalding. The TMV will need servicing, including descaling, at least annually to ensure all moving parts are free to move and the risk of Legionella proliferation reduced as Legionella can thrive and multiply in scale.

Ensure the correct TMV is selected as there are 3 types under the TMV scheme:

- Type 1 – A mechanical mixing valves with maximum temperature stop (including single lever taps).

- Type 2 – A thermostatic mixing valve which conform to BS EN 1111 and BS EN1287 (originally BS 1415 Part 2). These can have a maximum temperature stop.

- Type 3 – A thermostatic mixing valve with enhanced thermal performance complying with NHS Estates requirements.

To enquire about our water hygiene services or to speak to one of our experts contact us today.

Sources:

Great Britain: Health And Safety Executive, 2013. Legionnaires’ disease. Control Of Legionella Bacteria In Water Systems – Approved Code Of Practice. L8 4th ed.

Department of Health, 2017. Health Technical Memorandum 04-01: Supplement. Performance Specification D 08: Thermostatic Mixing Valves (Healthcare Premises). [ebook] Available at this link. [Accessed 21 May 2020].

Department of Health, 2016. Health Technical Memorandum 04-01: Safe Water In Healthcare Premises. Part A: Design, Installation And Commissioning. [ebook] Available at this link. [Accessed 21 May 2020].

Contains public sector information licensed under the Open Government Licence v3.0.

Image provided by Altecnic Ltd

ASBESTOS REGULATION COMPLIANCE CHECKER

ASBESTOS REGULATION COMPLIANCE CHECKER 0191 419 3116

0191 419 3116 contactus@franksportlock.co.uk

contactus@franksportlock.co.uk